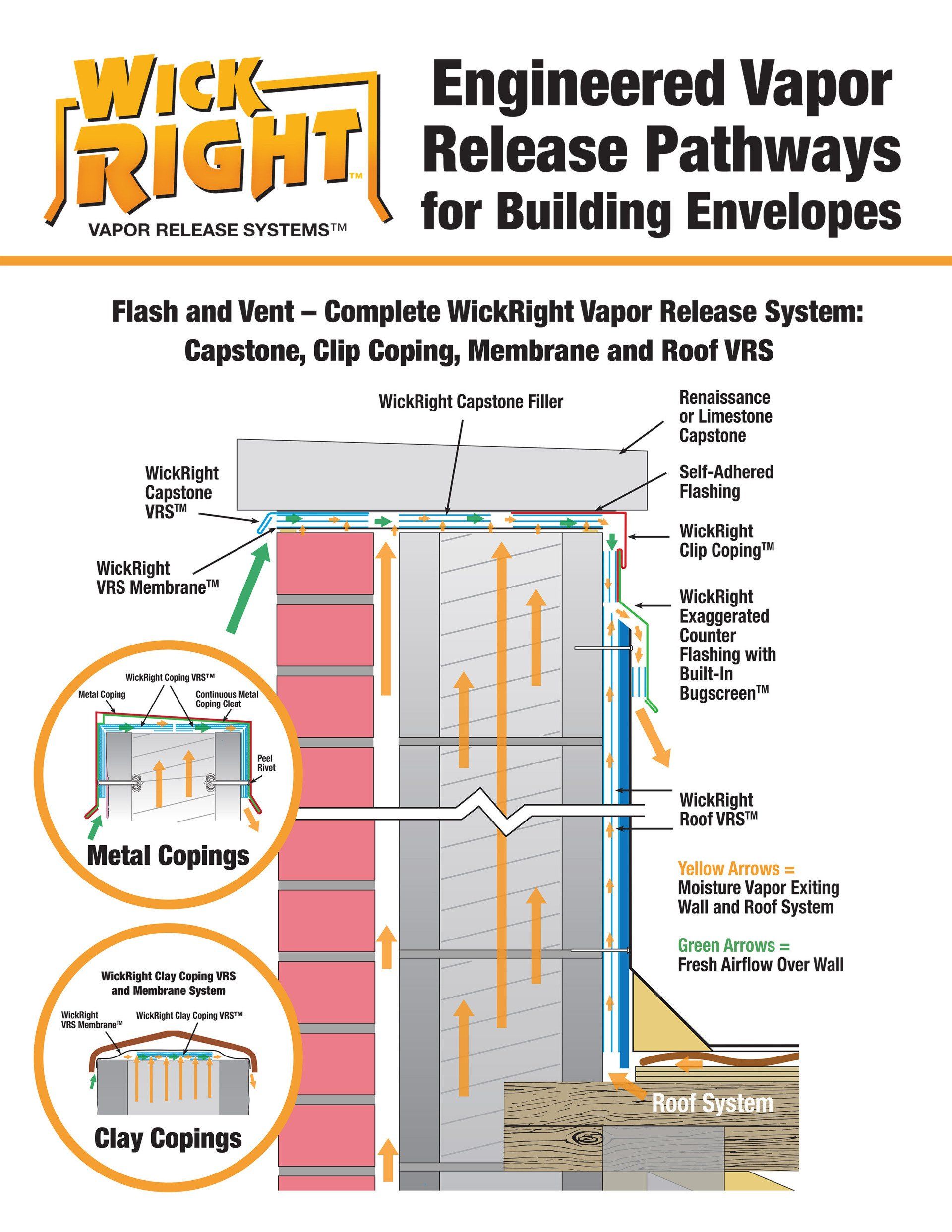

How WickRight Parapet Vents Work

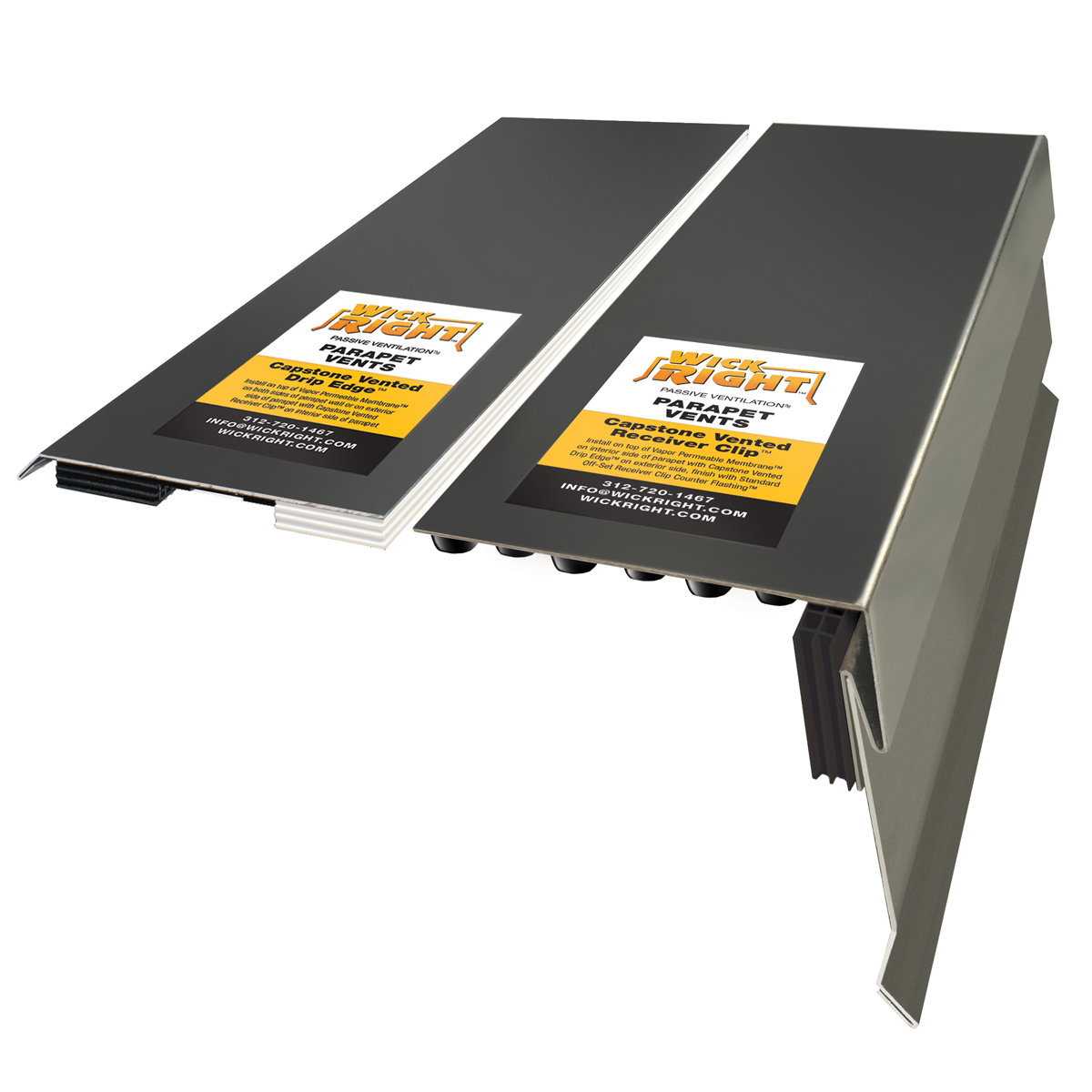

WickRight Vented Drip Edge and WickRight Vented Receiver Clip shown.

Both parapet vents are installed under capstones. Vented Drip Edge is installed on the exterior side of a parapet wall and Vented Receiver Clip is installed on the interior side of a parapet wall. Vented Drip Edge can also be installed on the interior side of the parapet for aesthetic purposes.

Both vents are a combination of Stainless Steel Metal Flashing and plastic airflow pathways. The metal profiles direct water away from the sides of parapet walls. The metal, combined with our Vapor Permeable Membrane installed below and self-adhered mason's vinyl flashing installed on top prevents all future water intrusion through the top of the parapet.

The plastic airflow pathways allow airflow into, across and and out of a parapet wall allowing trapped moisture vapor to exhaust from the wall core to the exterior. See details below.

Order WickRight

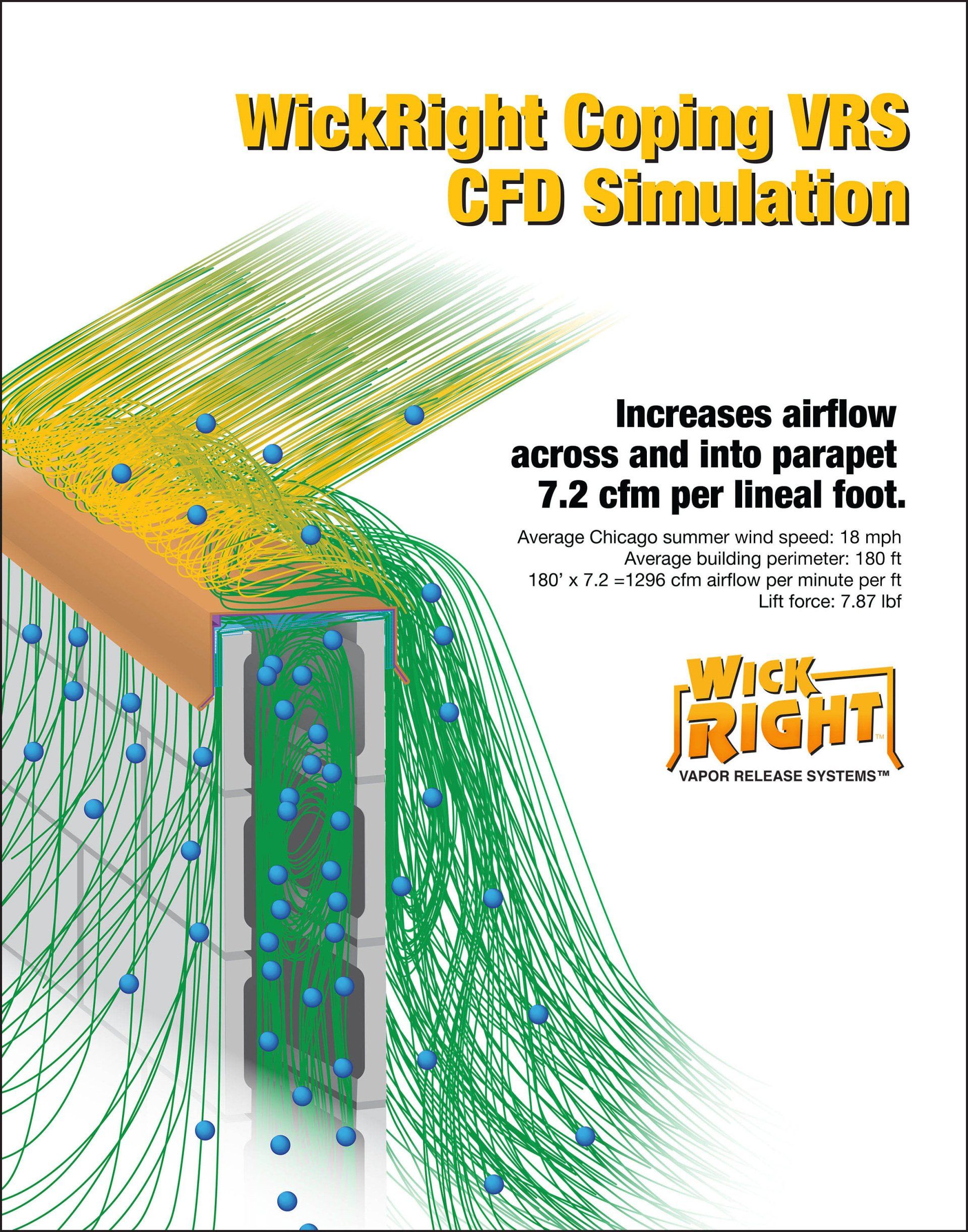

WickRight Testing - Computer Fluid Dynamics Simulations

Capstone Vented Drip Edge, Vented Receiver Clip and Metal Coping Vent

- Provide a -7.2 CFM draw per linear ft with 18 mph wind (avg wind speed Chicago summer day). This draw helps evacuate moisture vapor and dry out wet walls

- Produces lift force of 7.87 lbs per foot which pulls moisture vapor out of the wall

- Solar Drive and Wind promote continuous drying

Do the math -

Standard 180' perimeter on 3-flat in Chicago

7.2 CFM x 180 linear feet = 1296 CFM

Moisture Vapor Venting

ASTM & NFA Stats

WickRight Membrane -

Breatheable, yet virtually waterproof!

- ASTM-E96 vapor permeability rating - 108 perms

- Membrane withstands

19.1 psi vertical application of water for

20 minutes

Note: Membrane is installed horizontally within the wall assembly - no direct application of water is possible

- Holds

8 oz of standing water up to

9.5 hours with only

.040 grams of seepage

Vented Flashing

Installation stats

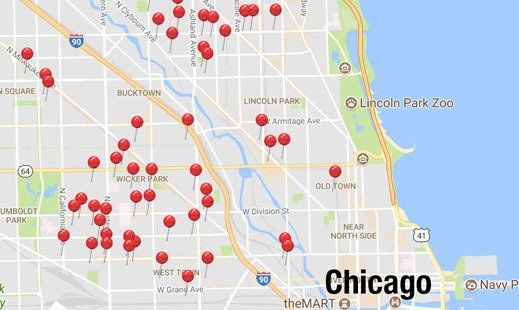

Over 150 WickRight Vented Flashing Installations – No Call Backs

- 82 Vented Drip Edge/Vented Receiver Clip Combo installations

- 47 Metal Coping Vent installations

- 38 Clay Coping Vent installations

- 74

Low-Slope Roof Vent installations

- 23 Fascia/Perimeter Vent installations

- 3

Hip & Valley Vent installations

Download Full Client map and Illinois Dept of Health Asthma Prevalence Overlay

Interior Rain Screen Results

New Construction Application

Restoration Application

Vertical installation of vent materials

on interior side of exterior walls

Benefits:

- Blocks 100% of moisture intrusion

- Eliminates condensation build-up

- Funnels moisture vapor to exit at parapet

- Acts as a Heat Exchange

- Translates to substantial cooling energy savings - 15º lower temperature on interior side of CMU wall

Client in Tampa –

"I was sitting on the roof and the steam coming out of the parapet actually burned my legs."

Vented Flashing Field Observations

Installation Monitoring

WickRight has monitored 15 buildings with Capstone Vented Drip Edge/Vented Receiver Clip or Metal Coping Vent and Low-Slope Roof Vent installations 36 months post installation.

Typical Results:

- Elimination of leaks at ceiling/floor levels within 1 week

- Improvement of air quality/elimination of smells within 2-3 weeks

- Significant reduction of indoor humidity readings within 3-4 weeks

- Improved HVAC system performance and reduced heating and cooling bills compared to previous season

Other Testing Results

Practical, Durable Designs

- Crush testing - Capstone Vented Drip Edge withstands up to 323 lbs of pressure

- Capstone Vented Drip Edge, Vented Receiver Clip, Clay Coping Vent and Metal Coping Vent work on all parapet widths - Capstone filler is available for installation in center of wall

- Fascia/Perimeter Vent designs available for installation on full and partial shingle roof tear offs

- Hip & Valley Vent - 2-in-1 solution - use on hips and valleys, makes it easier to work on tight multi-roof lines and reduces materials storage needs

- Do not use WickRight products with primers or sealants that contain Xylene

"I have, personally, seen this product installed on a number of buildings and find it to be one of the most innovative construction products, ever. It solves both the problems of flashing and venting, all in one."

– William Decker, Certified Master Inspector

Decker Homes Services

Email:

wjd@deckerhomeservices.com

Website: www.deckerhomesservices.com

"...New buildings have huge amounts of plastic materials, they don't "breathe." They are loaded with tree-farm grown and engineered lumber that is structurally adequate if kept dry, but extremely susceptible to moisture problems. Wet tree-farm lumber grows mold quickly and the material rots.

Even if there isn't any visible damage, there can be serious problems brewing. In addition, indoor air quality is greatly effected by moisture hidden in the walls causing mold growth ...

It's not good enough to treat a building with sealant and walk away thinking the problem is solved, because it's not. In some cases, sealants accelerate problems; they keep water out, but they also keep water in.

It's necessary to have continuous venting and vapor transfer out of the masonry. WickRight products and building repair techniques were perfected in the field, actually repairing buildings; it's not an abstract concept... WickRight is a necessary component of any moisture damage repair ... No other repair systems even come close to the WickRight systems, which are adaptable to all manner of buildings and all sorts of configurations ...

I've seen the WickRight systems work, and I would recommend it to anyone that is having moisture related problems with their building. I'd even recommend WickRight installation to homeowner's that aren't currently experiencing water problems as a preventative measure to insure that their home has satisfactory indoor air quality for healthy living."

– Kurt Mitenbuler

Home Inspector, Moisture Intrusion Expert

Licensed/Certified

Email:

kurt@chicagohomeprimer.com

Website: https://kurtmitenbuler.com/